Not known Details About Best Injector Cleaner

Table of ContentsAn Unbiased View of Best Injector CleanerThe Main Principles Of Best Injector Cleaner Some Ideas on Best Injector Cleaner You Should Know

A cutaway design of a fuel direct injected engine Fuel injection is the introduction of fuel in an internal combustion engine, most frequently automobile engines, by the methods of an injector. This short article focuses on fuel injection in reciprocating piston and rotary piston engines. All Diesel (compression-ignition) engines use fuel injection, and lots of Otto (spark-ignition) engines use fuel injection of one kind or another.

Normally, the only thing in common all fuel injection systems have is the absence of carburetion. There are two primary practical concepts of mix development systems for internal combustion engines: internal mixture formation, and external mixture development. A fuel injection system that utilizes external mixture development is called a manifold injection system; there exist 2 kinds of manifold injection systems: multi-point injection (port injection), and single-point injection (throttle-body injection).

There exist a number of various varieties of both direct and indirect injection systems, the most typical internal mix development fuel injection system is the common-rail injection system, a direct injection system. best injector cleaner. The term electronic fuel injection refers to any fuel injection system having an engine control unit. An ideal fuel injection system can exactly provide precisely the correct amount of fuel under a all engine operating conditions.

In practice an ideal fuel injection system does not exist, but there is a big range of various fuel injection systems with particular advantages and disdvantages. The majority of these systems were rendered obsolete by the common-rail direct injection system that is nowadays (2020) used in many guest cars. Common-rail injection permits gas direct injection, and is even much better suited for diesel engine fuel direct injection - best injector cleaner.

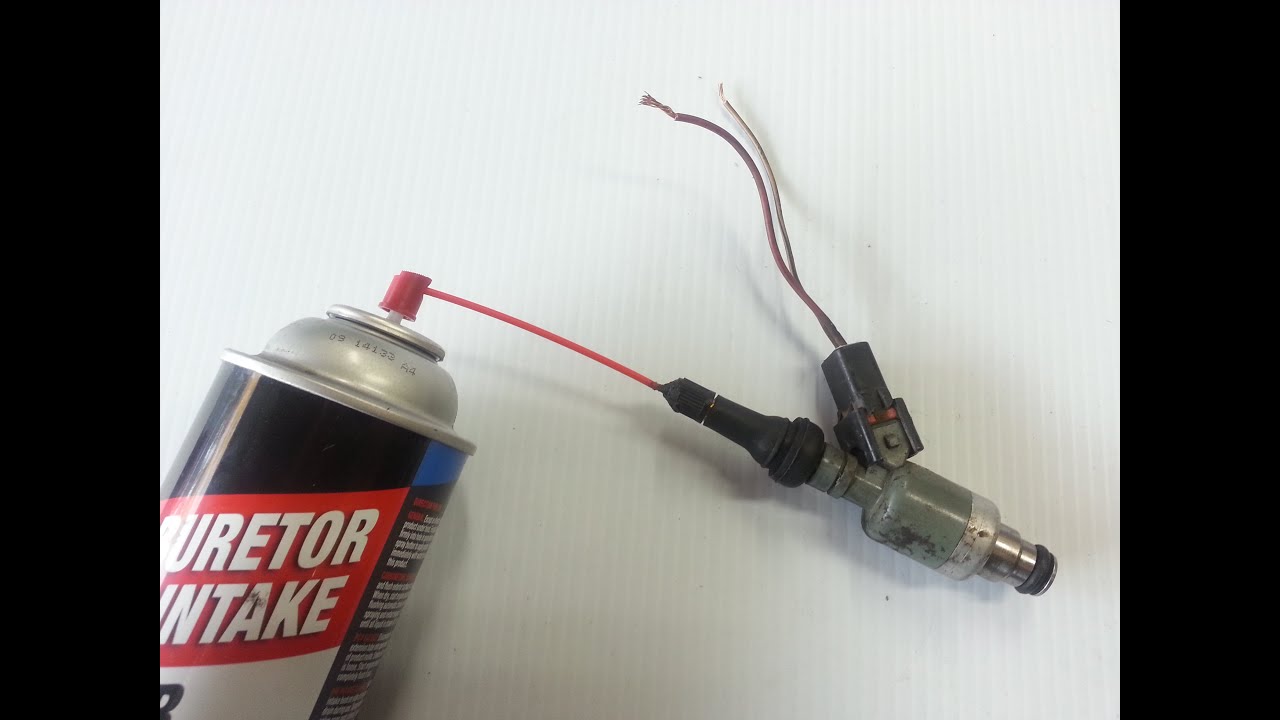

When creating a fuel injection system, a range of aspects needs to be taken into account, consisting of: All fuel injection systems consist of 3 fundamental components: they have at least one fuel injector (often called an injection valve), a gadget that creates sufficient injection pressure, and a gadget that meters the appropriate quantity of fuel.

The Only Guide for Best Injector Cleaner

Early mechanical injection systems (except air-blast injection) typically used injection valves (with needle nozzles) in combination with a fairly sophisticated helix-controlled injection pump hop over to here that both metered the fuel, and developed the injection pressure. They were well-suited for intermittently injecting multi-point injection systems in addition to all sorts of standard direct injection systems, and chamber-injected systems.

In contemporary engines, the fuel metering and injection valve actuation is typically done by the engine control unit (best injector cleaner). Therefore, the fuel injection pump does not have to meter the fuel or actuate the injection valves; it just needs to offer injection pressure. These modern-day systems are used in multi-point-injected engines, and common-rail-injected engines.

The introduction listed below shows the most typical kinds of mix formation systems in internal combustion engines. There are numerous different methods of characterising, organizing and describing fuel injection systems, the clade is based upon a differentiation between internal and external mixture development systems. Mixture formation systems Internal mixture development Indirect injection Direct injection Hydraulic injection Walldistributed injection Airdistributed injection Pumpe-Dse system Pump-rail-nozzle system Air-guided injection Wall-guided injection Spray-guided injection Standard helixcontrolled injection pump systems Lanova direct injection Afterchamber injection G-System (sphere combustion chamber) Gardner system (hemisphere combustion chamber) Saurer system (torus combustion chamber) Flat piston (combustion chamber between piston and head) External mix formation Constant vacuum carburettor Multistage carburettor Multi-barrel carburettor Float-chamber-less membrane carburettor BMW M88 engine with multi-point injection In an engine with external mixture formation, air and fuel are combined outside the combustion chamber, so that a premixed mixture of air and fuel is sucked into the engine.

There exist two main external mix development systems in internal combustion engines: carburettors, and manifold injection. The following description focuses on the latter. Manifold injection systems can likewise be considered indirect injection, but this article primarily uses the term indirect injection to describe internal mix formation systems that are not direct injection.

They can use numerous various injection plans. Single-point injection uses one injector in a throttle body installed similarly to a carburetor on an check this consumption manifold. As in a carbureted induction system, the fuel is blended with the air prior to the inlet of the intake manifold. Single-point injection was a fairly affordable way for automakers Learn More Here to decrease exhaust emissions to comply with tightening regulations while providing much better "driveability" (simple starting, smooth running, liberty from hesitation) than might be gotten with a carburetor.

This delayed the redesign and tooling expenses of these elements. Single-point injection was used thoroughly on American-made traveler automobiles and light trucks throughout 19801995, and in some European vehicles in the early and mid-1990s. Multi-point injection injects fuel into the consumption ports just upstream of each cylinder's intake valve, rather than at a main point within an intake manifold.

Best Injector Cleaner for Beginners

Manifold injected engines can use numerous injection schemes: continuous, and periodic (synchronised, batched, consecutive, and cylinder-individual). In a constant injection system, fuel streams at all times from the fuel injectors, however at a variable circulation rate. The most typical vehicle continuous injection system is the Bosch K-Jetronic, introduced in 1974, and utilized up until the mid-1990s by various cars and truck makers.

In an engine with an internal mixture development system, air and fuel are mixed just inside the combustion chamber. For that reason, only air is drawn into the engine during the consumption stroke. The injection scheme is always periodic (either consecutive or cylinder-individual). There are two different types of internal mix formation systems: indirect injection, and direct injection.